However, deeper trenches increase excavation and spoils- handling costs during construction, as well as maintenance costs over the long term.

How deep are engineers willing to dig the trench? The lower the duct bank is in the ground, the better, as topsoil moisture and ambient temperatures are cooler and less variable. Design, therefore, becomes a matter of carefully calibrated tradeoffs. An efficient system maximizes the number of conduits and the size of the ducts while minimizing the depth of burial and cost of the backfill.

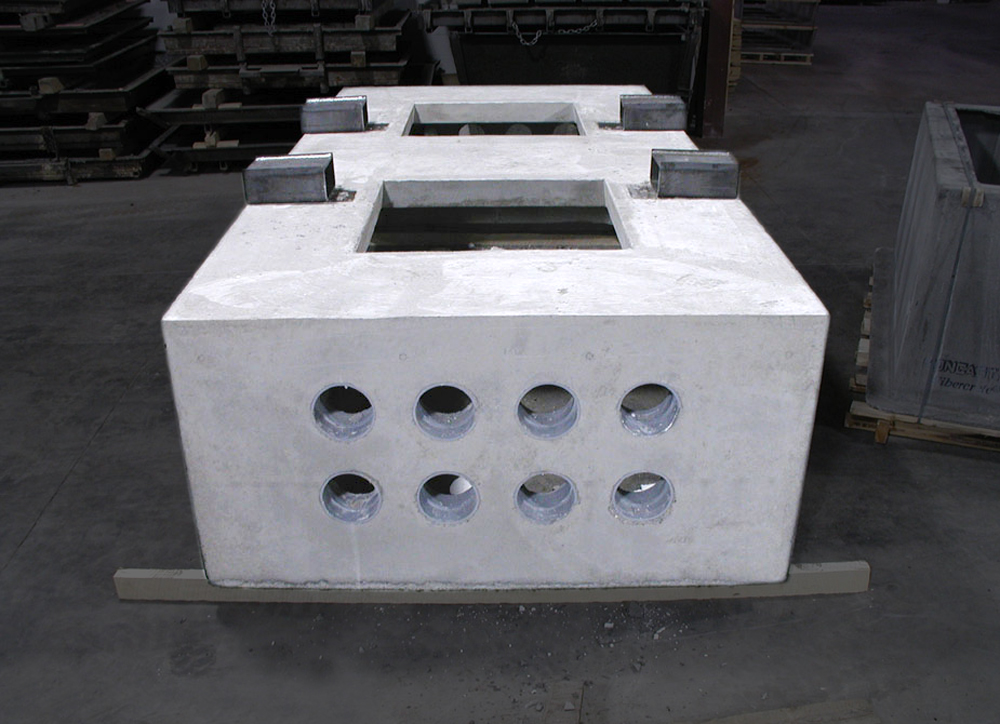

Two of these factors are dictated by the project parameters: the electrical load-the amount of power demanded by the facility-and the cabling system. The performance and construction costs for underground transmission lines are influenced by five factors. A professional, safe installation of an underground system requires actual measurement and evaluation of thermal properties, which is relatively easy to perform in the field and in the laboratory.ĭon’t rely on concrete alone to achieve performance The key takeaway is that heat transfer in soil can be a complex process and 90 is not a magic number. “And the one thing you cannot change about the design, at the point when everyone discovers that the assumption of 90 is wrong, is the soil.” Knowing that soil conditions vary, how did the guidebook decide to assume a rho value of 90 for soil? The reason is that there is no ASTM standard for thermal concrete, and conventional uses for concrete in construction have not required a lot of thought about its ability to conduct heat. “I’ve seen rho values in native soils from 126 all the way up to 220,” says Jean-Philippe Thierry, US Ready-Mix Performance Director at Holcim. However, thermal resistivity of soil is not a constant, as soil conditions vary from location to location. When designing trench systems, engineers often assume that the rho value in the soil is 90, as the NEC Guidebook, Division 26, specifies. The backfill and soil surrounding the duct bank control the rho value, along with the duct bank itself: its size, the number of conduits and the depth to which it’s buried. Measure-don’t assume soil thermal properties Here are some considerations for mitigating risk and achieving the intended level of performance to avoid any big surprises that can bring the construction project to a halt after shovels hit the ground. These miscalculations can destroy a project schedule-and budget-with construction stoppages and system design reworks. If calculations are faulty, the design can be inefficient or, even worse, insufficient. Trench depth, soil conditions, and the thermal properties of the duct-bank concrete encasement and backfill materials all influence how much conduit is needed to achieve the right level of performance. To build a high-powered, uninterrupted supply system, engineers design conduits in the duct-bank system within very specific parameters. Whether you’re designing a duct-bank system for a data center, a wind farm, or an electrical substation, it is important that you anticipate risks and implement preventive solutions to avoid potential outage problems. It is essential that data centers and high-demand electrical facilities have a reliable power supply to keep operations up and running 24 hours per day, 7 days per week, and 365 days per year. Thermally Conductive Concrete: Duct-Bank Design Considerations for Mission-Critical Facilities

0 kommentar(er)

0 kommentar(er)